- Home

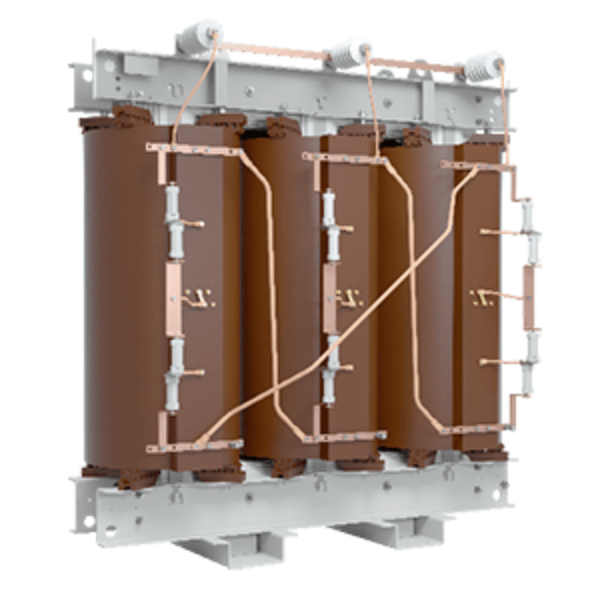

- Resin Cast Transformer

Resin Cast Transformer

Table of Contents

Togglebest Resin Cast Transformer Manufacturers in India

Beta Power Controls LLP is a trusted Resin Cast Transformer Manufacturers in India. With over 17 years of industry expertise, we provide reliable, energy-efficient, and custom-built Resin Transformers for industrial, commercial, and infrastructure applications. As an ISO 9001:2015-certified company, our transformers ensure seamless power regulation, voltage stability, and long-term durability, making us a top Resin Transformer exporter in India.

We cater to businesses across India, the Middle East, Europe, Africa, and Southeast Asia, offering customized solutions, precision engineering, and global shipping. Our products are designed for superior performance, fire safety, and compliance with international standards.

Middle East

Europe

Asia

Africa

Our Products

Contact us

- No. 4/305, Mother India Industrial Estate, Bodipalayam, Coimbatore – 641 105

Product Specifications

At Beta Power Controls LLP, our resin transformers are designed to meet international quality standards while providing exceptional reliability, efficiency, and safety. Below are the key specifications of our transformers:

Electrical Specifications

- Voltage Rating: Up to 35kV (including dual voltage options)

- Capacity Range: 30 kVA to 40,000 kVA (AN)

- Frequency: 50Hz / 60Hz

- Tapping Range: ±2x2.5% (other options available on request)

- Vector Group: Dyn11, Yyn0, or other configurations as per customer requirements

- Insulation Class: F-Class (155°C) / H-Class (180°C)

Mechanical Specifications

- Cooling System: Air Natural (AN) / Air Forced (AF)

- Protection Enclosure Ratings: IP00, IP20, IP23, IP54, IP56

- Construction: Vacuum cast resin insulation ensuring moisture-proof, pollution-resistant, fireproof properties

- Core Material: High-quality grain-oriented silicon steel core for low losses and high efficiency

- Winding Material: Aluminum or Copper with high dielectric strength

- Mounting: Stationary or Rolling Base with bi-directional wheels for easy mobility

Environmental Specifications

- Ambient Temperature: Up to 40°C

- Altitude Rating: Suitable for up to 1000m above sea level (higher ratings available on request)

- Noise Level: Low noise operation, meeting IEC standards

- Temperature Monitoring: PT100 sensors for real-time thermal protection

Compliance & Certifications

Manufactured as per: IEC 60076, IS 1180, IS 9815, CE, RoHS

Routine Tests Conducted:

Types of Servo Voltage Stabilizers

Cast Resin Dry Type Transformer (CRT)

A cast resin dry type transformer (CRT) is a type of transformer that uses epoxy resin to encapsulate its primary and secondary windings. This protects the windings from moisture, dust, corrosion, and other environmental factors that can affect their insulation and performance.

Feature | Cast Resin Dry Type Transformer (CRT) | Vacuum Pressure Impregnated Transformer (VPI) |

Best For | Indoor installations, humid areas, fire-sensitive zones | Outdoor installations, seismic zones, high-temperature areas |

Insulation | Encapsulated with epoxy resin | Impregnated with polyester resin |

Mechanical Strength | Moderate | High resistance to shocks & vibrations |

Fire Resistance | High | Medium |

Maintenance | Maintenance-free | Requires minimal maintenance |

Applications | Hospitals, malls, IT data centers, industrial plants | Renewable energy, marine, mining, outdoor power substations |

Vacuum Pressure Impregnated Transformer (VPI)

A vacuum pressure impregnated transformer (VPI) is a type of transformer that uses class H polyester resin to impregnate its windings under vacuum and pressure. This eliminates any air gaps or voids in the insulation, enhancing its mechanical strength, dielectric strength, and thermal stability.

Feature | Cast Resin Dry Type Transformer (CRT) | Vacuum Pressure Impregnated Transformer (VPI) |

Best For | Indoor installations, humid areas, fire-sensitive zones | Outdoor installations, seismic zones, high-temperature areas |

Insulation | Encapsulated with epoxy resin | Impregnated with polyester resin |

Mechanical Strength | Moderate | High resistance to shocks & vibrations |

Fire Resistance | High | Medium |

Maintenance | Maintenance-free | Requires minimal maintenance |

Applications | Hospitals, malls, IT data centers, industrial plants | Renewable energy, marine, mining, outdoor power substations |

Applications of Dry Type Transformer

Industrial Applications

- Used in manufacturing plants, textile mills, and chemical industries.

- Powers heavy machinery, steel plants, and automotive assembly lines.

- Ensures safe energy distribution in hazardous environments.

Commercial & Infrastructure Applications

- Shopping malls, office buildings, and high-rise apartments use dry transformers for stable power distribution.

- Integrated into metro rail systems, airports, and smart city projects.

- Supports commercial complexes requiring uninterrupted power supply.

Renewable Energy Systems

- Essential for solar farms, wind energy plants, and hydroelectric stations.

- Helps stabilize grid fluctuations from renewable sources.

- Offers energy-efficient power transmission while reducing carbon footprint.

Healthcare & Data Centers

- Hospitals and medical centers depend on dry transformers for stable voltage supply.

- Data centers and IT parks require them for continuous, noise-free energy flow.

- Prevents power fluctuations affecting sensitive equipment.

Marine & Mining Industry

- Ideal for ships, offshore platforms, and naval bases due to moisture resistance.

- Provides safe and stable power to underground mining operations.

Fire-Prone & Seismic Zones

- Used in fire-sensitive areas such as oil refineries, tunnels, and underground substations.

- Designed to withstand seismic activities, making them suitable for earthquake-prone regions.

Advantages of Dry Type Transformer

Why Choose Beta Power Controls for the Best Resin Transformer Manufacturers in India?

Industry Leadership & Innovation

- 17+ years of expertise in power transformation solutions.

- Trusted global supplier exporting to UAE, Saudi Arabia, UK, Africa, and Asia.

- Advanced epoxy resin encapsulation technology for high-efficiency performance.

- Cutting-edge R&D ensuring superior insulation and heat resistance.

Premium Quality & Certifications

- ISO 9001:2015 certified with global safety and industry compliance.

- High-efficiency transformers with minimal power loss.

- Custom-built designs tailored for specific industrial and commercial applications.

- Stringent quality control and rigorous testing for reliability.

Frequently Asked Questions

What industries use Resin Cast Transformers?

They are widely used in industrial, commercial, infrastructure, healthcare, and renewable energy sectors.

Do you offer custom-built Resin Cast Transformers?

Yes! We provide tailored designs based on voltage, capacity, and application needs.

What certifications do your transformers comply with?

Our products are ISO 9001:2015, IEC 60076-11, and RoHS-compliant.

How long does international shipping take?

Shipping timelines vary, but we ensure fast delivery with complete logistics support.

What is the warranty on your Resin Cast Transformers?

All our transformers come with a comprehensive warranty and after-sales technical support.

Looking for a Safe and Reliable Power Solution for Harsh Environments?

and built for mission-critical use.

Looking for a Safe and Reliable Power Solution for Harsh Environments?

Beta Power’s Resin Cast Transformers are fireproof, moisture-resistant, and built for mission-critical use.